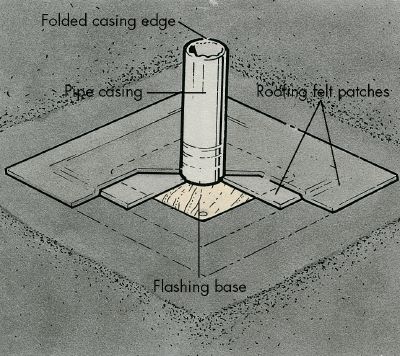

The roof vent pipe is installed cut through the roof and around the pipe attached to the roof is surrounded with rubber boot as insulation for the gap between the pipe and roof.

How do vent pipes get cut into a metal roof.

Once we had the pipe extension connected we figured out where the new vent pipe would need to pass through the roof using a piece of scrap wood held flush with the pipe.

Cutting through the tar material and sheathing will typically require a depth of 1 to 1 1 4 inches.

Where the scrap wood hit the understructure of the roof we drilled a hole straight through to the outside.

Measure the body of the vent.

It is a vertical pipe attached to a drain line and runs through the roof of your home.

Make the mark dark enough and visible enough to be seen when the cut is being made.

It also allows fresh air into the plumbing system to help water flow smoothly through the drain pipes however no water runs through the plumbing vent pipe.

Here are a few tricks that really will help if you.

But it truly is rewarding.

Remember to allow for the lip on the vent mechanism that will fit over the opening and rest on the surface of the roof.

3 hold the saw s blade 1 inch above the roof remove the blade guard and depress the trigger.

Optimal air movement not only promotes temperature regulation and energy efficiency but also reduces the risk of moisture related issues like condensation build up.

Outline the exact cut that will need to be made on the panel with a marker.

There are many possible parts of the roof potentially leaking but one of the most common ones is the area around the roof vent.

Using the tape measure determine the size of the cut into the roof that will be necessary to insert the vent into the space.

The vent stack is the pipe leading to the main roof vent.

Run a tape measure over the diameter of the pipe and add 1 2 to 3 4 inch to that before making the cut.

Selecting metal roof and wall panels is a strategic investment for the life of a building.